Product Overview

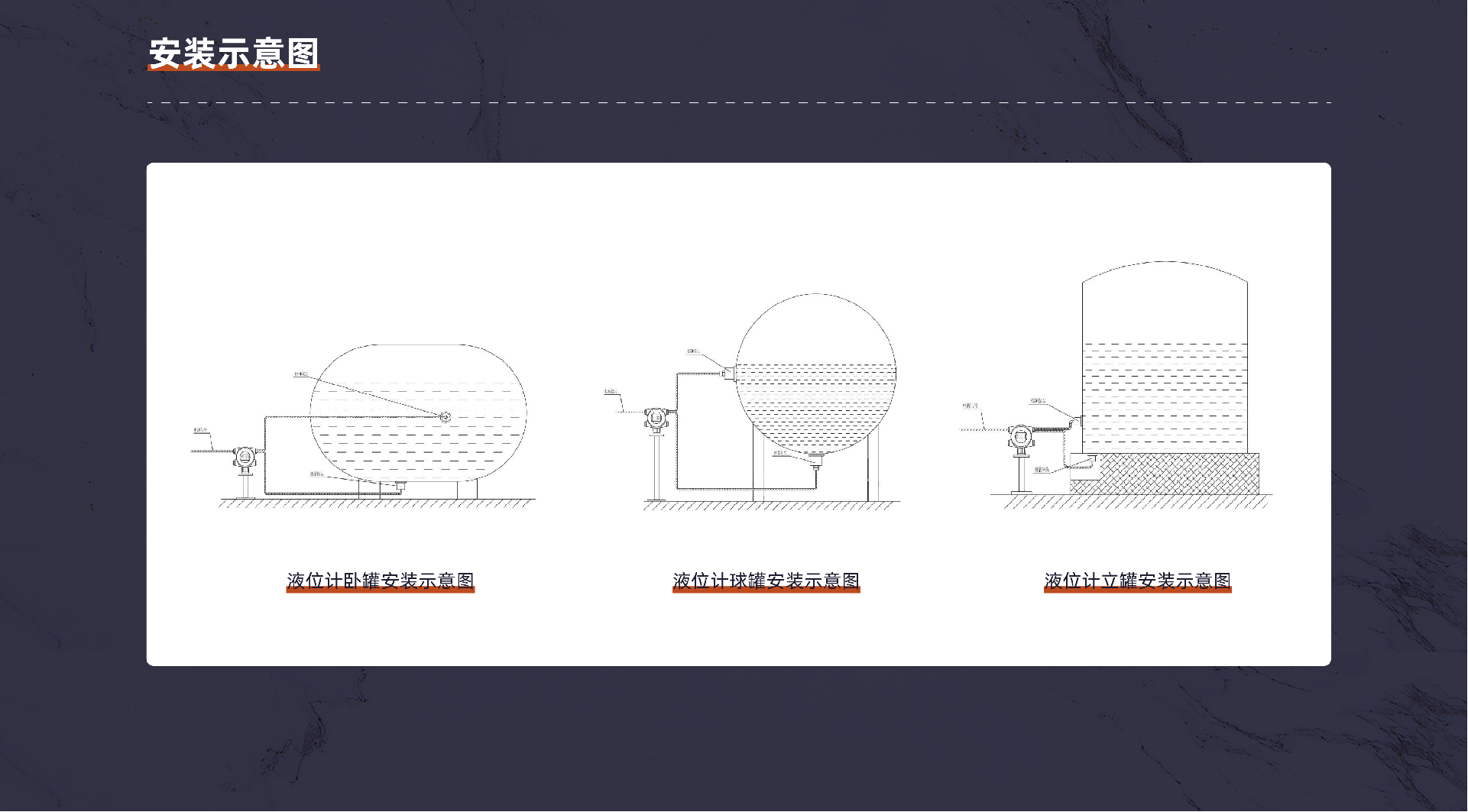

External mounted level gauge (hereinafter referred to as level gauge) is an intelligent explosion-proof instrument developed by our company that uses sonar ranging principle to measure the liquid level inside a sealed container from the outside. This product breaks the traditional measurement and installation method of liquid level gauges, achieving true non-contact measurement of liquid level in closed containers without opening holes. The sonar sensor (probe) is externally mounted on the bottom of the outer side of the container, without the need for hot work on the tested container and without affecting production. Truly achieved non-stop production and no hot work installation. It can accurately measure the liquid level of various flammable, explosive, toxic and other major hazardous media in high-temperature, high-pressure and sealed containers.