Product Overview

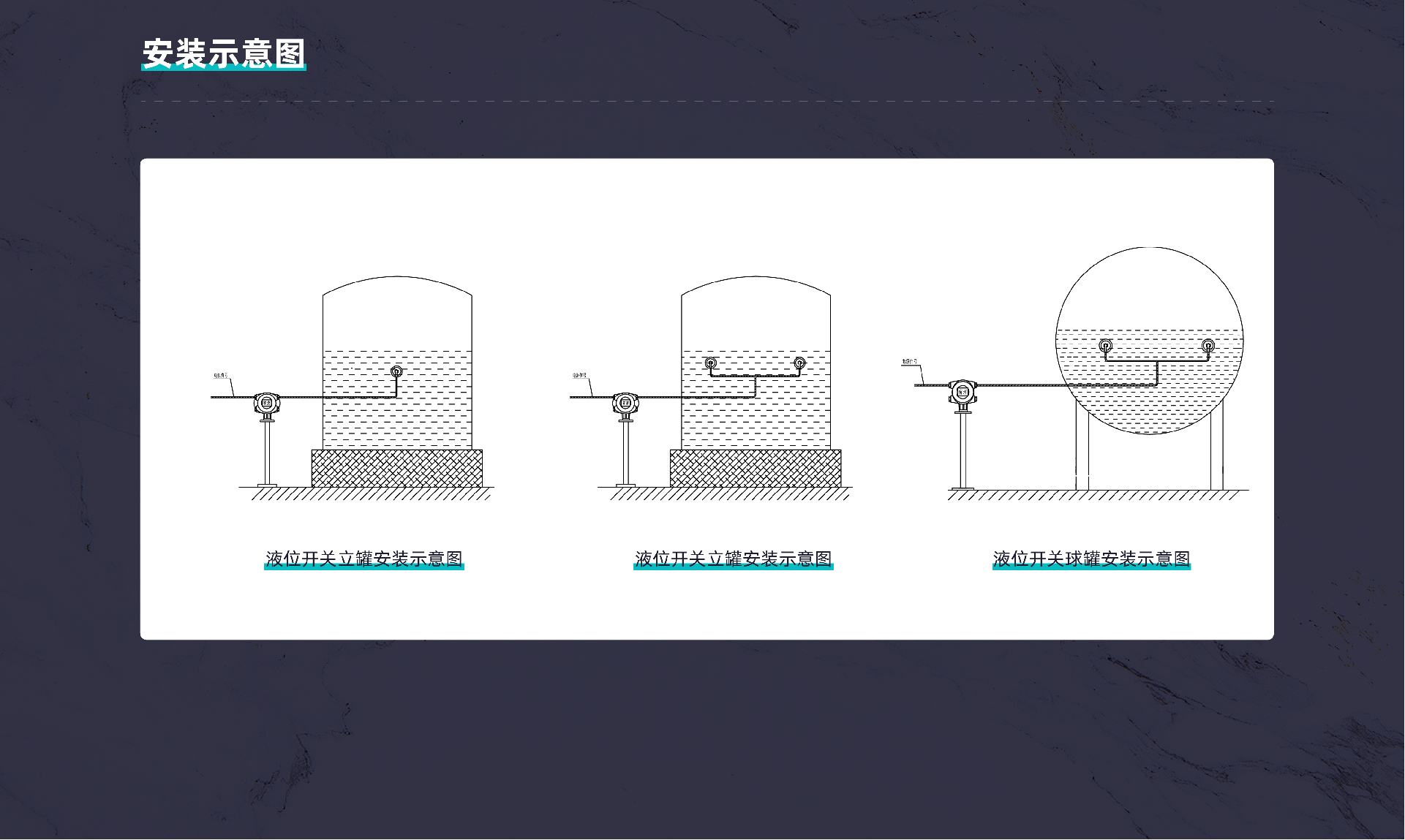

External mounted liquid level switch is a new type of liquid level measuring instrument. Its working principle is to use the sonar pulse signal emitted by the sensor to propagate and reflect in the container wall and medium, and then be received by the sensor. By detecting and calculating the pulse signal during this process, the change in liquid level at the monitoring point can be determined. The liquid level switch can output relay signals to the downstream electrical or system to complete the monitoring and control of the liquid level in the storage tank. The product adopts an external installation method, without moving the tank or using fire, and is safe and reliable to use with high sensitivity. Its comprehensive performance has advanced levels both domestically and internationally, providing strong guarantees for safety production. The high and low liquid level alarm system for storage tanks is widely used in industries such as petroleum, chemical, and power.